The Mechanics of Cost Efficiency in Diesel-powered Engines

In this article, we will explore how diesel-powered engines can achieve cost efficiency through various mechanical adjustments and technological advancements. The aim is to understand these key elements that contribute towards optimizing fuel use, reducing emissions, and minimizing operational costs. By examining the core components and innovative enhancements, we will uncover how diesel engines remain relevant in today’s energy-conscious society. This comprehensive analysis will draw from diverse areas such as engine mechanics, fuel advancements, maintenance practices, and diesel mechanics expertise. Ultimately, our exploration will reflect on the intersection of these factors with environmental regulations and emerging technologies, highlighting the role of skilled diesel mechanics in achieving optimal performance.

Diesel Engine Fundamentals

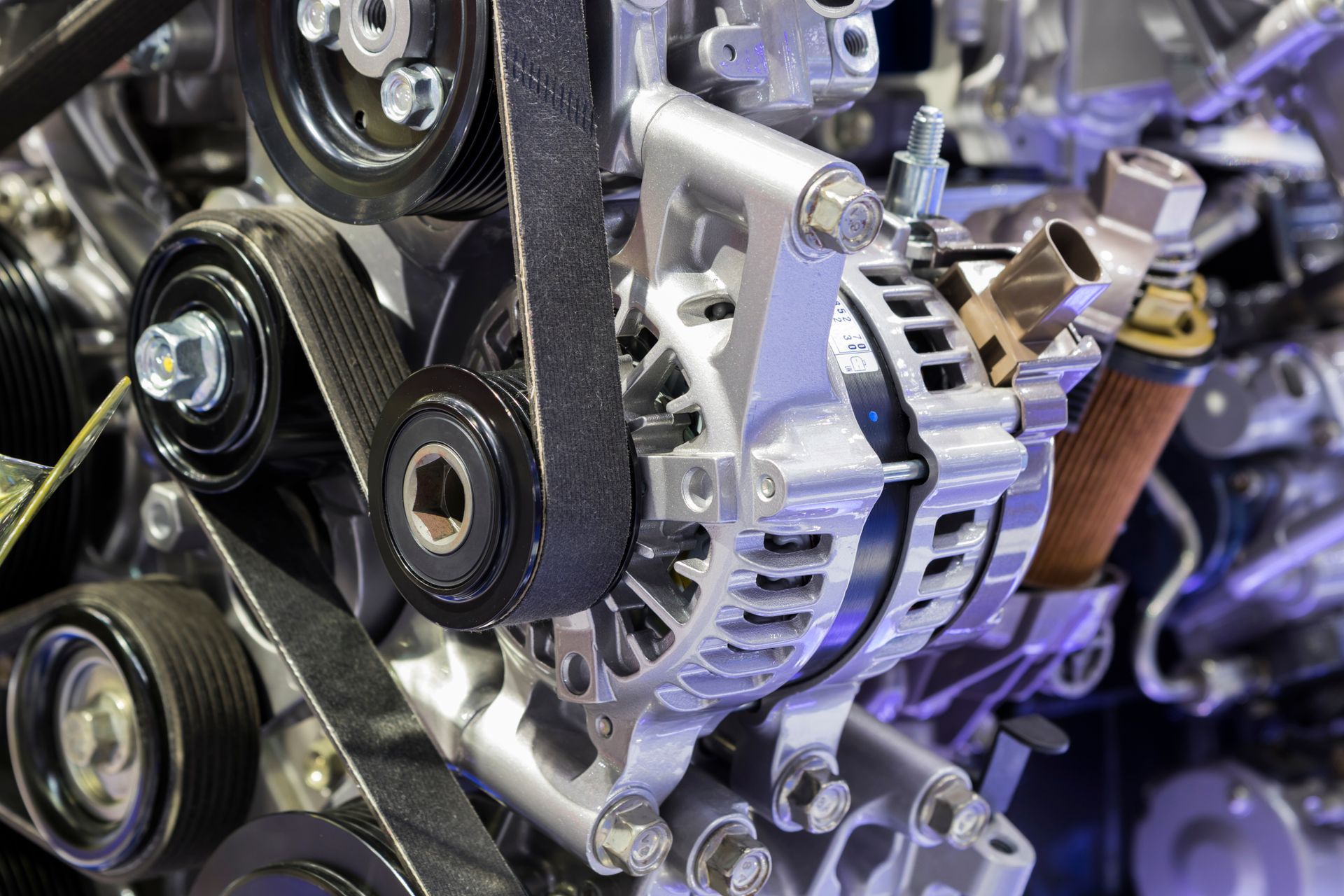

Diesel engines operate on the principles of the combustion cycle, where air and fuel are utilized to generate power. This process is initiated by compressing air within the engine cylinders, which raises the air temperature. Fuel is then injected into the hot air, causing ignition. The power stroke drives the pistons, converting the chemical energy in the fuel into mechanical energy. Understanding the intricate details of the combustion cycle helps in optimizing performance and enhancing fuel efficiency for diesel engines, and is a core responsibility of experienced diesel mechanics.

The role of turbocharging in diesel engine efficiency cannot be overstated, as turbochargers increase the engine's power output without a significant increase in fuel consumption. By forcing more air into the combustion chamber, turbochargers increase engine efficiency and power. This process allows diesel engines to maintain higher compression ratios, optimizing combustion and fuel use. According to Diesel Fleet, diesel trucks achieve up to 35% more miles per gallon, resulting in significant cost savings for high-mileage or fuel-demanding applications. Diesel mechanics play an essential role in maintaining and calibrating turbocharged systems to ensure peak performance.

Fuel Technology Advancements

The introduction of Ultra-Low Sulfur Diesel (ULSD) has been a significant advancement, aimed at reducing harmful emissions while maintaining engine performance. ULSD contains significantly lower sulfur content compared to traditional diesel, which directly leads to lower sulfur dioxide emissions. The transition to ULSD is not only beneficial for the environment but also for engine health, as it leads to less acid formation and better lubrication of engine parts. Diesel mechanics ensure engines are properly adapted to handle ULSD and similar fuels, maintaining efficiency and longevity. This fuel technology represents how environmental concerns can drive innovation within the diesel engine industry. Moreover, ULSD remains a critical factor in regulatory compliance and efficiency drive.

Fuel additives are another advancement that aims to enhance diesel engine efficiency by improving fuel properties and combustion characteristics. Additives can clean fuel injectors, prevent water build-up, and enhance lubrication, which collectively improve engine performance. By optimizing the combustion process, these additives help in maximizing fuel economy and reducing emissions. Diesel mechanics are integral in applying these solutions effectively and monitoring their impact on engine performance. Furthermore, modern engines benefit from predictive fuel monitoring systems that track fuel usage patterns and conditions, allowing diesel mechanics to make data-driven adjustments.

Engine Design Enhancements

Recent enhancements in engine design focus on the adoption of lightweight materials, which significantly improve fuel efficiency by reducing the vehicle's overall weight. Using high-strength alloys, aluminum, and composites minimizes the engine weight without compromising durability or performance. This weight reduction translates directly to less energy required to propel the vehicle, resulting in lower fuel consumption. Diesel mechanics are often responsible for integrating and maintaining these advanced materials in practical applications. By integrating lightweight materials, manufacturers can create diesel engines that are both powerful and economically viable, highlighting the ongoing importance of skilled diesel mechanics in modern engine design.

Cylinder deactivation is a technological innovation allowing certain engine cylinders to be automatically turned off when full power is not required. This feature achieves fuel savings by reducing engine displacement during low-load conditions, such as highway cruising. When power demand increases, the deactivated cylinders reactivate seamlessly to provide the needed output. This functionality not only improves fuel efficiency but also reduces engine wear by minimizing active components. Diesel mechanics ensure cylinder deactivation systems operate correctly, making it an effective tool in achieving cost-efficient diesel engine operation.

Maintenance Practice Impacts

Regular servicing and maintenance practices are fundamental to sustaining diesel engine efficiency and prolonging engine life. Timely service intervals help in identifying and rectifying potential issues before they develop into costly repairs. Consistent maintenance ensures that components are clean and functioning correctly, which directly contributes to optimal fuel usage and reduced emissions. Diesel mechanics are essential in performing these tasks, ensuring engines remain in peak condition. Proper maintenance routines, including air filter replacement and injector cleaning, can significantly enhance engine performance and reliability, emphasizing the vital role of diesel mechanics.

Engine tuning for optimal performance is an advanced maintenance strategy that can significantly influence diesel engine efficiency. Tuning adjusts engine parameters to achieve better power, torque, and fuel economy. Utilizing diagnostics and predictive maintenance, engines can be fine-tuned for specific operational conditions. Diesel mechanics oversee these procedures, using their expertise to optimize performance and prevent failures. The cost-benefit analysis of tuning practices reveals substantial long-term savings by preventing inefficiencies and costly repairs, highlighting the value of skilled diesel mechanics in every phase of engine upkeep.

Technological Innovations and Trends

Automated Engine Management Systems (AEMS) are revolutionizing the approach to diesel engine efficiency by integrating smart technology for performance optimization. These systems continuously analyze engine parameters, allowing automated adjustments to fuel flow, air intake, and emissions control. Diesel mechanics work alongside these technologies to ensure proper integration and operation, bridging traditional mechanical expertise with modern automation. By enabling precise calibrations based on real-time data, these systems facilitate significant enhancements in fuel efficiency and emissions reductions.

The rise of Smart Sensors and the Internet of Things (IoT) is transforming diesel engine management by providing real-time insights and automation capabilities. Smart sensors monitor various engine parameters such as temperature, pressure, and fuel consumption, offering insights into engine health and performance. IoT connectivity allows these sensors to communicate with centralized systems for predictive diagnostics and maintenance alerts. Diesel mechanics leverage these insights to make informed adjustments, ensuring engines operate efficiently and sustainably.

Environmental and Regulatory Considerations

Diesel engines are subject to an array of emission standards designed to minimize environmental harm caused by fossil fuel combustion. These regulations mandate the adoption of cleaner, more efficient engine technologies that limit nitrogen oxides and particulate matter emissions. Compliance with such standards necessitates innovative approaches and advanced technologies, often guided by diesel mechanics who ensure engines meet operational and environmental standards. By keeping pace with evolving regulations, diesel engines can maintain relevance and efficiency in the transportation and industrial sectors.

The impact of environmental regulations extends beyond engine design to influence fuel composition and technology adoption within the diesel industry. Governments worldwide have introduced incentives and mandates that promote cleaner diesel alternatives like ULSD and biodiesel blends. Diesel mechanics play a key role in adapting engines to these fuels and monitoring performance, driving technological shifts toward sustainability. These measures encourage manufacturers and operators to prioritize green technologies and efficiency enhancements.

Diesel-powered engines are critical components in various industries, and understanding the mechanics of cost efficiency within these engines can significantly impact operational savings. By combining advancements in technology, design, maintenance, and environmental considerations, diesel engines can continue to evolve as powerful, efficient, and sustainable power sources. Diesel mechanics remain essential in implementing best practices, troubleshooting complex systems, and maximizing performance. Through innovative approaches in fuel technology and engine enhancements, manufacturers are redefining the potential of diesel engines. Embracing maintenance best practices and emerging technologies ensures continued relevance in efficiency-driven markets. As environmental regulations evolve, diesel engines remain integral to balancing power needs with responsible energy use. For expert diesel engine maintenance, upgrades, and performance solutions, contact Jag's Pro Truck Shop today to keep your fleet running at peak efficiency.

Share On: